TL;DR

|

In a world where same-day delivery is becoming the norm and 73% of consumers expect better fulfillment speed than they did five years ago, traditional warehouse operations are no longer enough.

Retailers are being pushed to the edge, not just by customer demand but also by rising labor costs, supply chain disruptions, and the complexity of managing thousands of SKUs across multiple locations.

Manual stock checks and delayed vendor reports are causing missed sales, operational bottlenecks, and frustrated customers. This is why AI in warehousing is no longer optional.

Artificial Intelligence transforms retail warehousing by automating stock movement, improving inventory accuracy, and delivering real-time insights into vendor performance. Companies leading this shift, like Amazon and Walmart, are using AI to optimize operations; they’re redefining what efficiency looks like in retail logistics.

In this blog, we’ll explain how AI integrates with warehouse systems, its benefits to stock and vendor management, and how global leaders use it to stay ahead.

AI in Warehousing Explained: How Technology Drives Smart Operations

In warehousing, AI refers to using artificial intelligence technologies to improve and automate warehouse operations. This includes tracking inventory, predicting stock levels, optimizing storage space, and managing vendor performance.

Conventional warehouse systems often rely on manual processes or static rules, such as fixed reorder points and periodic inventory checks. In contrast, AI-driven systems continuously learn from real-time data, including sales trends, supplier lead times, and seasonal demand patterns. This allows the system to make smarter decisions without human intervention.

For example, instead of waiting for a stockout or relying on manual inventory checks, AI can predict when a product is likely to run low and recommend the best time to reorder. It can also identify unusual patterns in inventory movement, such as shrinkage or overstock, and alert warehouse managers to take action early.

AI in warehousing also supports automation technologies like robotics and machine vision. These tools can pick, pack, and move goods efficiently, reducing errors and speeding up order fulfillment.

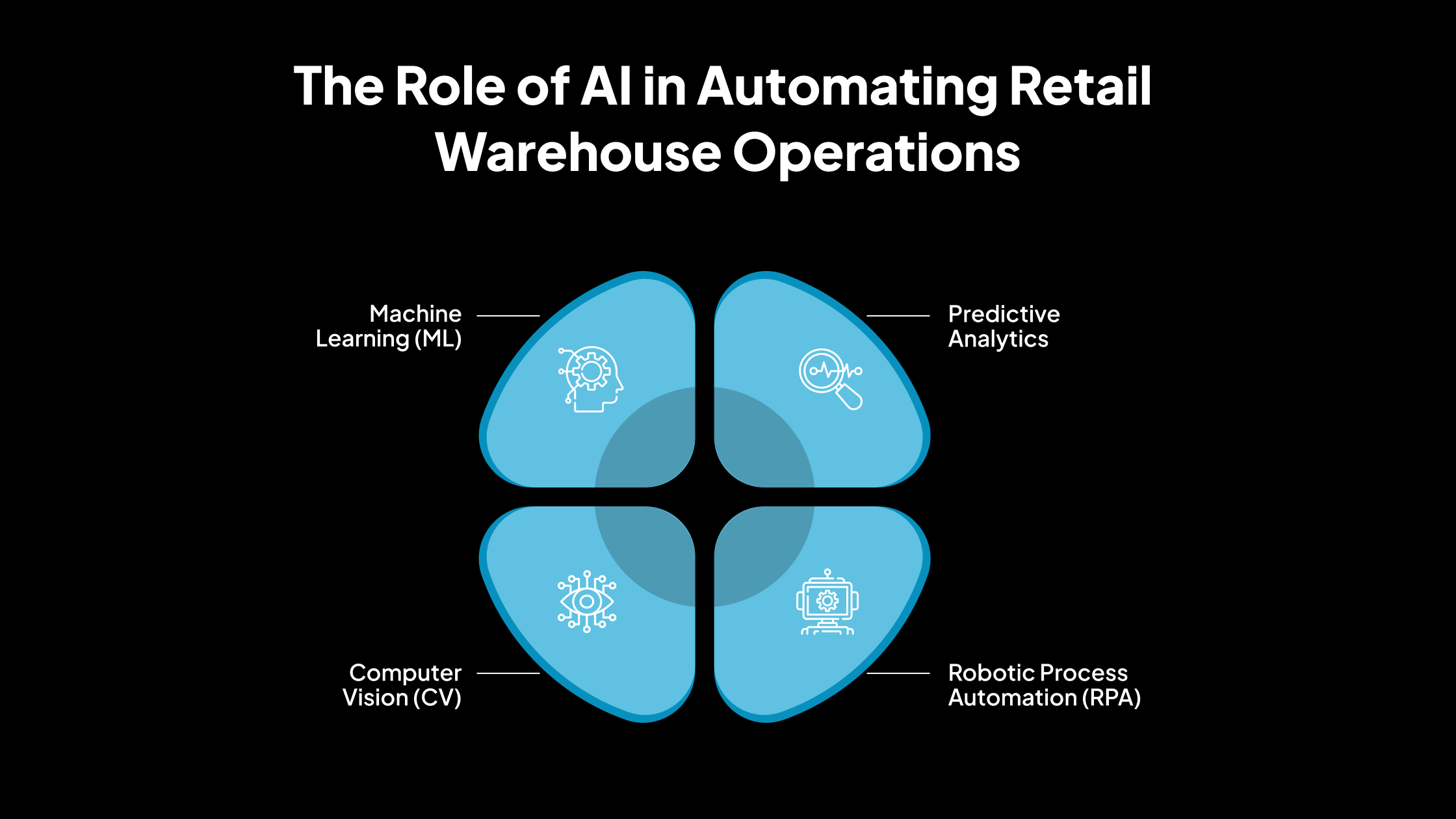

The Role of AI in Automating Retail Warehouse Operations

Below is a detailed explanation of how AI in warehousing drives retail warehouse automation, enhances accuracy, reduces manual effort, and optimizes inventory and logistics operations across the board.

1. Machine Learning (ML)

ML algorithms analyze historical data to identify patterns and make informed decisions.

- Demand Forecasting: ML models predict future product demand by analyzing sales trends, seasonal patterns, and external factors, enabling optimal inventory levels and reducing stockouts or overstock situations.

- Inventory Optimization: By learning from past sales and inventory data, ML helps determine the ideal stock quantities, minimize holding costs, and maximize sales opportunities.

2. Computer Vision (CV)

CV enables machines to interpret and process visual information, enhancing warehouse operations.

- Inventory Tracking: CV systems monitor inventory levels in real-time by analyzing images and videos, ensuring accurate stock records and timely replenishment.

- Quality Control: CV identifies damaged or mislabeled products during the picking and packing, reducing errors and returns.

3. Robotic Process Automation (RPA)

RPA uses software robots to automate repetitive and rule-based tasks.

- Order Processing: RPA automates data entry and order management, speeding up processing times and reducing manual errors.

- Reporting: Automated generation of reports on inventory levels, order statuses, and vendor performance enhances decision-making and operational transparency.

4. Predictive Analytics

Predictive analytics utilizes statistical techniques to forecast future events based on historical data.

- Maintenance Scheduling: Predictive analytics forecasts maintenance needs by analyzing equipment usage patterns, preventing unexpected breakdowns and downtime.

- Supply Chain Management: Forecasting demand fluctuations and potential disruptions allows for proactive procurement and distribution strategies. adjustments

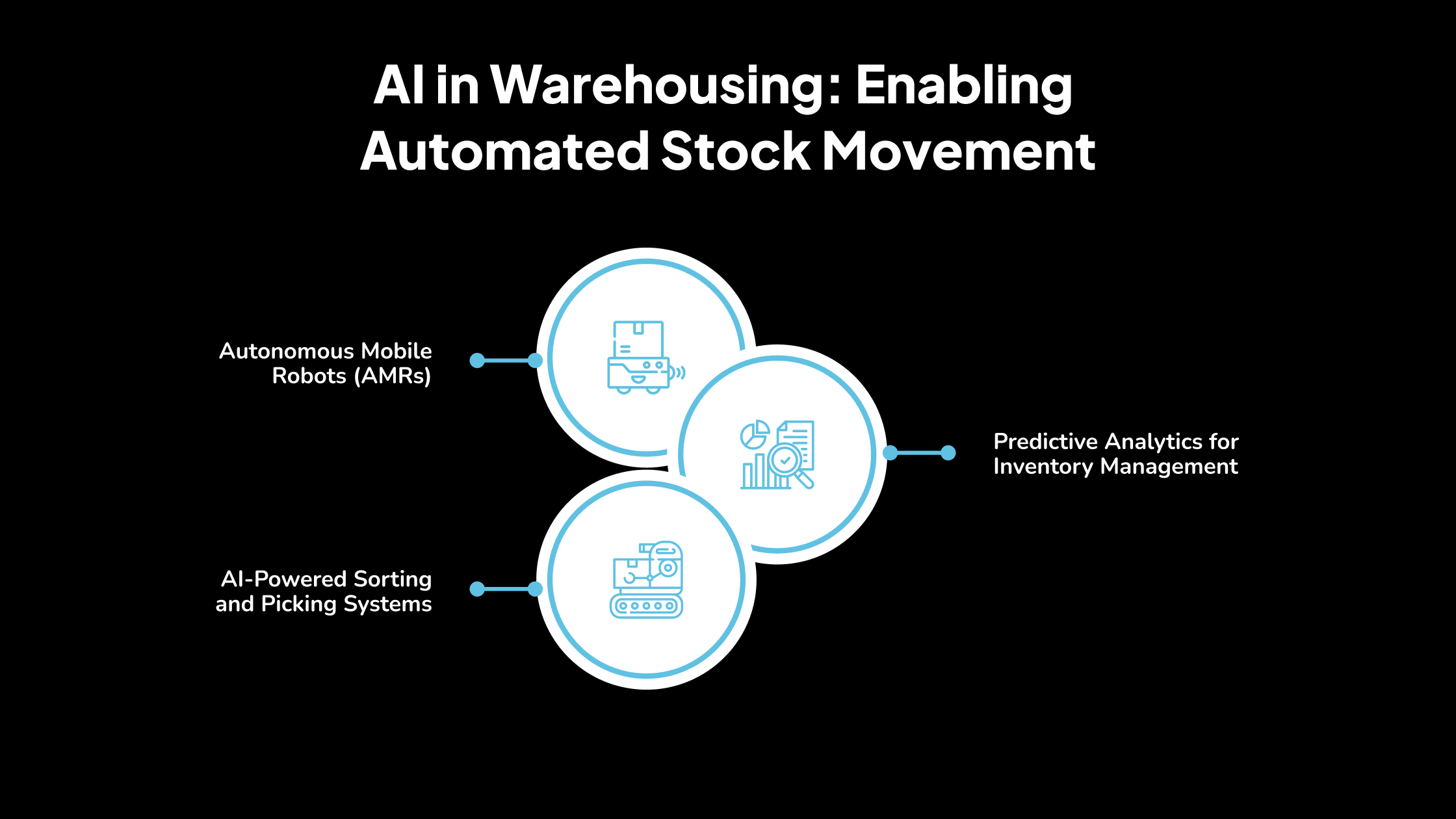

AI in Warehousing: Enabling Automated Stock Movement

Here’s how AI in warehousing is powering automated stock movement—improving accuracy and efficiency from shelf to shipment.

1. Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots move goods within warehouses without human intervention. Built-in sensors, maps, and AI-based navigation systems guide them.

For example, Amazon uses robots like Proteus and Hercules to transport inventory across its fulfillment centers. Proteus is designed to safely navigate shared workspaces, while Hercules specializes in lifting and moving heavy shelves.

AMRs follow optimized routes, avoid obstacles, and adjust paths in real-time. Their implementation reduces manual labor, minimizes handling errors, and speeds up internal transport operations.

2. AI-Powered Sorting and Picking Systems

Sorting and picking are labor-intensive tasks that AI helps automate with high precision. Robotic systems like Amazon’s Sparrow and Cardinal use computer vision, machine learning, and robotic arms to identify, grab, and sort items.

Sparrow recognizes various product shapes and barcodes and uses suction-based end-effectors to pick items. Cardinal sorts packages by scanning and placing them into specific bins. These systems improve picking accuracy, reduce the time taken to process orders, and support continuous operations without fatigue or inconsistency.

3. Predictive Analytics for Inventory Management

AI-driven predictive analytics tools help warehouses forecast product demand and manage inventory levels more effectively. These tools analyze historical sales data, seasonal trends, lead times, and customer behavior to predict future stock requirements.

Algorithms adjust forecasts as new data becomes available, improving accuracy over time. This allows warehouses to maintain optimal inventory, avoiding excess stock and shortages. Predictive models also support automated reordering systems, ensuring timely replenishment and improving overall supply chain efficiency.

AI in Warehousing: Transforming Vendor Reporting and Performance Tracking

Below is how AI in warehousing improves vendor reporting by automating data collection, enabling real-time performance tracking, and supporting smarter supply chain decisions.

1. Real-Time Data Collection and Analysis

AI-powered systems use data from IoT devices and warehouse sensors to track real-time inventory. These devices monitor key variables such as stock levels, product movement, delivery times, and storage conditions.

AI algorithms then process the collected data to identify trends, detect irregularities, and generate actionable insights. For example, if a particular item moves slower than expected, the system can flag it for further review. This real-time visibility allows warehouse managers and vendors to make informed decisions quickly, reducing the risk of delays or stock imbalances.

2. Automated Report Generation

AI can automate the creation of vendor reports, eliminating the need for manual data compilation. These reports typically include inventory status, order fulfillment rates, shipment delays, return rates, and supplier delivery performance.

Because the data is continuously updated and processed by the AI system, the reports are accurate, timely, and consistent. Automated reporting improves communication between retailers and vendors, enabling them to align more effectively on inventory planning, replenishment cycles, and overall supply chain coordination.

3. Performance Monitoring and Optimization

AI tools help businesses continuously evaluate vendor performance by analyzing delivery accuracy, timeliness, order quality, and compliance with service-level agreements. These systems can highlight performance gaps, flag recurring issues, and rank vendors based on reliability and efficiency.

With this information, businesses can make data-driven decisions, such as negotiating better terms, offering performance-based incentives, or switching to more reliable suppliers. Over time, this leads to stronger vendor relationships and a more resilient supply chain.

Essential Benefits of AI Integration in Retail Warehousing

Below is a list of essential benefits demonstrating how AI in warehousing delivers measurable improvements across retail operations.

1. Operational Efficiency

Integrating AI into warehouse operations automates routine tasks such as inventory tracking, order picking, and sorting. This automation leads to faster processing times and reduces the reliance on manual labor, thereby decreasing labor costs.

AI systems can operate continuously without fatigue, ensuring consistent productivity levels. Automation can reduce labor costs by 30% to 40% over the next five years. Warehouses with AI robots experience a 20% reduction in labor costs.

2. Accuracy and Reliability

70% of warehouse operators report that AI has improved their inventory accuracy. AI technologies enhance warehouse operations’ precision by minimizing stock handling and reporting errors.

AI systems can detect discrepancies and ensure accurate inventory records through real-time data analysis and machine learning algorithms, improving order fulfillment reliability.

3. Scalability

AI solutions offer scalability, allowing warehouses to adapt to increasing demands without a proportional resource increase. As business volumes grow, AI systems can handle additional workloads efficiently, ensuring operations remain smooth and responsive to market changes.

AI integration in warehouses is associated with a 25% reduction in warehouse footprint thanks to optimized space use. AI-powered systems can scale and adapt to dynamic business needs, allowing warehouses to handle fluctuating demand.

4. Enhanced Decision-Making

AI-driven forecasting can reduce errors by between 20% and 50%, translating into reduced lost sales and product unavailability of up to 65%. AI provides data-driven insights that support informed strategic choices in warehouse management.

By analyzing vast amounts of data, AI can identify trends, forecast demand, and optimize inventory levels, enabling managers to make proactive decisions that enhance overall efficiency.

Challenges and Considerations in Implementing AI in Warehousing

While AI in warehousing offers significant advantages, it also presents specific challenges. Below are a few key considerations retailers must keep in mind.

1. Initial Investment Costs

Implementing AI in retail warehousing requires a significant initial financial investment. Costs may include purchasing hardware such as autonomous robots, sensors, computing infrastructure, software development, and integration.

Additionally, businesses may need to update warehouse layouts or systems to accommodate AI technology. While these investments can lead to long-term savings and improved efficiency, the upfront costs can be a barrier for small and mid-sized companies.

2. Workforce Adaptation

Introducing AI systems changes the nature of warehouse operations, requiring employees to adapt to new roles and technologies. This often involves training workers to operate and maintain AI-enabled equipment or use data analytics tools.

As some manual tasks become automated, there may also be concerns about job displacement. Managing this transition effectively involves reskilling staff and creating new opportunities in supervision, maintenance, and data management roles.

3. Data Security and Privacy

AI systems in warehousing rely on the continuous collection and analysis of large volumes of data, including product information, vendor details, and operational workflows. Ensuring the security and privacy of this data is essential.

Companies must implement strong cybersecurity measures, such as encryption, secure access controls, and compliance with data protection regulations. Any breach or misuse of data could lead to operational disruptions and loss of trust among stakeholders.

Practical Applications of AI in Retail Warehouse Operations

Leading retailers have adopted AI-driven solutions to enhance warehouse automation, inventory management, and supply chain efficiency. Below are four notable examples:

1. Amazon: Warehouse Automation with Robots

Amazon revolutionized its fulfillment centers by acquiring Kiva Systems in 2012, integrating over 750,000 robots to automate warehouse operations. These robots transport entire shelves (pods) to human workers, reducing walking time and increasing picking efficiency. Advanced models like Proteus navigate autonomously, enhancing safety and productivity.

2. Walmart: Computer Vision for Inventory Monitoring

Walmart implemented AI-powered computer vision systems to monitor shelf stock levels in real-time. In a pilot across 70 Canadian stores, cameras scanned shelves at intervals, detecting low stock and triggering replenishment alerts. This automation improved on-shelf availability and reduced manual inventory checks.

3. Zara: AI-Driven Inventory Management

Zara employs AI to streamline its fast-fashion supply chain. By analyzing sales data and customer feedback, AI forecasts demand, optimizes inventory levels, and reduces overstock. RFID technology integration enables real-time product tracking, enhancing stock accuracy and responsiveness to market trends.

4. Alibaba’s Cainiao: Smart Logistics Network

Cainiao, Alibaba’s logistics arm, leverages AI and big data to optimize warehouse operations and delivery networks. AI algorithms predict demand patterns, manage inventory, and coordinate logistics across a vast network, ensuring timely deliveries and efficient resource utilization.

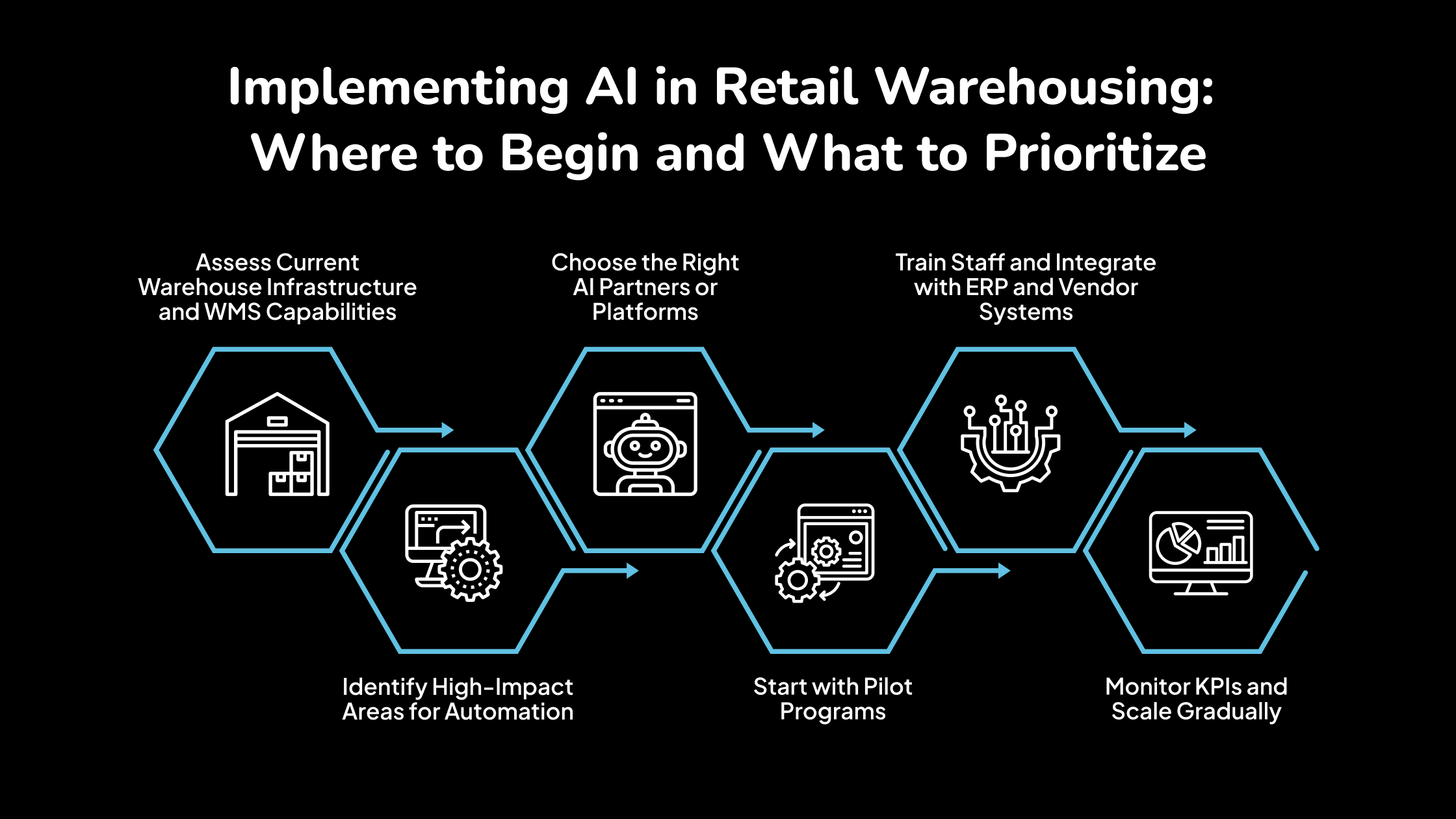

Implementing AI in Retail Warehousing: Where to Begin and What to Prioritize

A structured approach is essential for successfully implementing AI in warehousing. The steps below outline a practical roadmap that retailers can follow:

1. Assess Current Warehouse Infrastructure and WMS Capabilities

Evaluate your warehouse layout, equipment, and Warehouse Management System (WMS). Understand what data is currently collected, how it’s processed, and whether your systems support integration with AI tools. This step helps identify gaps and sets a foundation for future improvements.

2. Identify High-Impact Areas for Automation

Look for repetitive warehouse processes prone to errors or create bottlenecks, such as inventory checks, order picking, or report generation. These are ideal candidates for automation through AI, as improvements here can deliver quick and measurable results.

3. Choose the Right AI Partners or Platforms

Select AI vendors or platforms that align with your operational needs and technical environment. Evaluate solutions based on their ability to integrate with your existing systems, scalability, user-friendliness, and the level of support offered.

The Avahi AI platform offers a powerful solution for helping businesses harness the full potential of artificial intelligence without needing to manage multiple disconnected tools.

Avahi’s platform enables businesses to harness artificial intelligence’s full potential without managing multiple disconnected tools.

4. Start with Pilot Programs

Before committing to a full rollout, implement a small-scale pilot, such as using AI for automated inventory tracking or generating vendor performance reports. This allows you to test functionality, gather feedback, and measure effectiveness with minimal risk.

5. Train Staff and Integrate with ERP and Vendor Systems

Ensure warehouse teams, IT staff, and relevant departments are trained to use the new AI tools. Seamless integration with ERP, procurement, and vendor systems is critical for real-time data flow and efficient operations.

6. Monitor KPIs and Scale Gradually

Track key performance indicators (KPIs) such as inventory accuracy, order fulfillment speed, and cost savings. Use these insights to refine your approach and expand AI applications across additional warehouse functions at a controlled pace.

Discover Avahi’s AI Platform in Action

At Avahi, we empower businesses to deploy advanced Generative AI that streamlines operations, enhances decision-making, and accelerates innovation—all with zero complexity.

As your trusted AWS Cloud Consulting Partner, we empower organizations to harness AI’s full potential while ensuring security, scalability, and compliance with industry-leading cloud solutions.

Our AI Solutions include

- AI Adoption & Integration – Utilize Amazon Bedrock and GenAI to enhance automation and decision-making.

- Custom AI Development – Build intelligent applications tailored to your business needs.

- AI Model Optimization – Seamlessly switch between AI models with automated cost, accuracy, and performance comparisons.

- AI Automation – Automate repetitive tasks and free up time for strategic growth.

- Advanced Security & AI Governance – Ensure compliance, fraud detection, and secure model deployment.

Want to unlock the power of AI with enterprise-grade security and efficiency? Get Started with Avahi’s AI Platform!

Frequently Asked Questions(FAQs)

1. What is AI in warehousing, and how does it work?

In warehousing, AI uses artificial intelligence technologies, like machine learning, computer vision, and robotics, to automate and optimize warehouse operations. It analyzes real-time data to make decisions such as predicting stock levels, recommending reorders, tracking inventory, and monitoring vendor performance.

2. How does AI help reduce stockouts and overstocking?

AI predicts demand by analyzing historical sales, seasonal trends, and supplier lead times. It then recommends optimal reorder points and quantities, minimizing the risk of stockouts and excess inventory.

3. What warehouse tasks can be automated with AI?

Common warehouse tasks that AI can automate include inventory tracking, stock movement, order picking, sorting, quality control, and report generation. AI also automates vendor performance monitoring and maintenance scheduling.

4. How does AI improve vendor reporting?

AI automates the collection and analysis of real-time inventory and supplier data. It generates accurate reports on order fulfillment rates, delivery timelines, return rates, and vendor reliability, helping businesses make more informed decisions.

5. Is AI in warehousing only for large retailers like Amazon?

No. While large retailers lead adoption, many AI platforms are designed to be scalable and accessible for small to mid-sized retailers. Pilot programs and modular integration make starting small and expanding over time feasible.